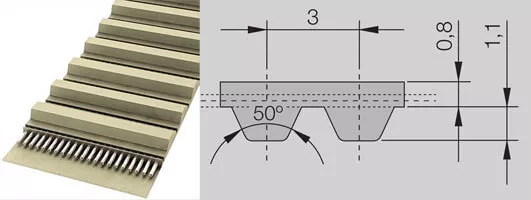

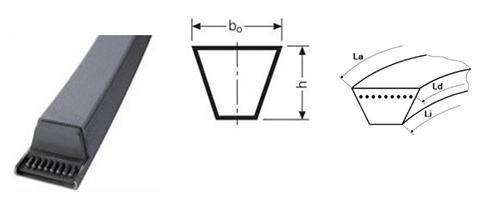

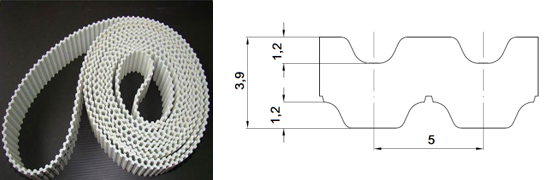

ContiTech AGCTD 1120 C8M

Specifications

Identification on the belt : Made in Germany CONTITECH DO NOT CRIMP CTD 1120 C8M

Trademark : CONTI®SYNCHROCHAIN

Manufacturer : ContiTech AG (Германия)

Belt dimensions:

| Tooth step | t | мм | 8 |

| Thickness | hs | мм | 5.6 |

| Tooth height | ht | мм | 3.4 |

| Nominal length | Lp/Lw | мм | 1120 |

| Number of teeth |

140 | ||

| Minimum pulley diameter | dw | мм | 56.02 |

| Width | bo | мм | 105 |

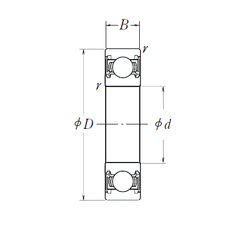

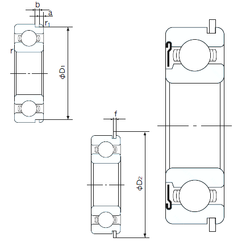

Подшипник 6000DDU

Manufacturer: NSK-RHP

Sizes: 10x26x8 (mm)

Weight:: 0.018 (kg)

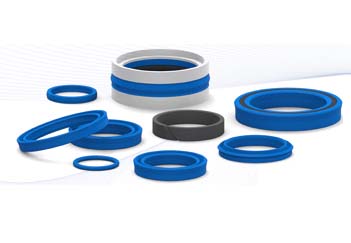

K21 NBR(19x25x6)

Manufacturer: KASTAS

Sizes: 19x25x6 (mm)

Manufacturer: ContiTech AG

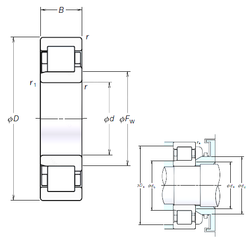

Подшипник NUP 222 EM

Manufacturer: NSK-RHP

Sizes: 110x200x38 (mm)

Weight:: 5.37 (kg)

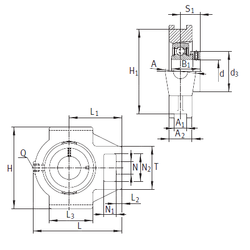

ПОДШИПНИКОВЫЙ УЗЕЛ ШАРИКОВЫЙ РАДИАЛЬНЫЙ RTUE60

Manufacturer: INA-FAG

ШАРИКОПОДШИПНИК РАДИАЛЬНО-УПОРНЫЙ С ЧЕТЫРЕХТОЧЕЧНЫМ КОНТАКТОМ QJ214-TVP

Manufacturer: FAG

Sizes: 70x125x24 (mm)

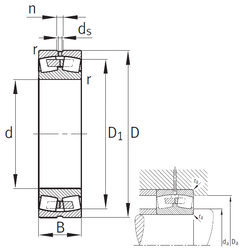

ПОДШИПНИК РОЛИКОВЫЙ РАДИАЛЬНЫЙ САМОЦЕНТРИРУЮЩИЙСЯ 24156-B-K30

Manufacturer: FAG

Sizes: 280x460x180 (mm)

Weight:: 118 (kg)

D 280 32x7110 Li / 7186 Ld

Manufacturer: ContiTech AG

AT5 DD

Manufacturer: ContiTech AG

Подшипник 6216ZNR

Manufacturer: NACHI

Sizes: 80x140x26 (mm)

Weight:: 1.40 (kg)

INSTALLING BEARINGS

Approximately 16% of all early pill accidents are caused by faulty mounting (generally excessive force) and lack of proper tools.

DROPPING BEARINGS

The need for dismantling (removal) of the bearing can be caused by several reasons: failure of the bearings, disassembly of other parts of the mechanism, and so on.

SELECTION OF FUEL OILS

The use of grease to lubricate the bearings ensures smooth operation and maximum reliability of bearings, even in extreme conditions.